Constraints

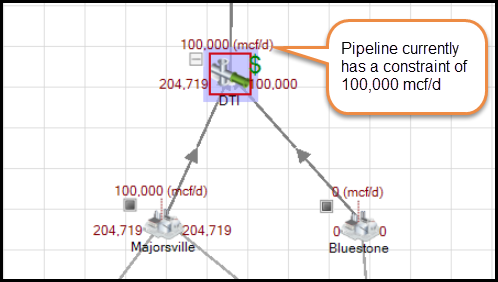

Constrained facilities will have a box drawn around them (red=gas, green=oil, blue=water, light blue=steam) provided that the "Highlight Constraints" flag is checked on the data layers (options to the right of the Network diagram).

Click image to expand or minimize.

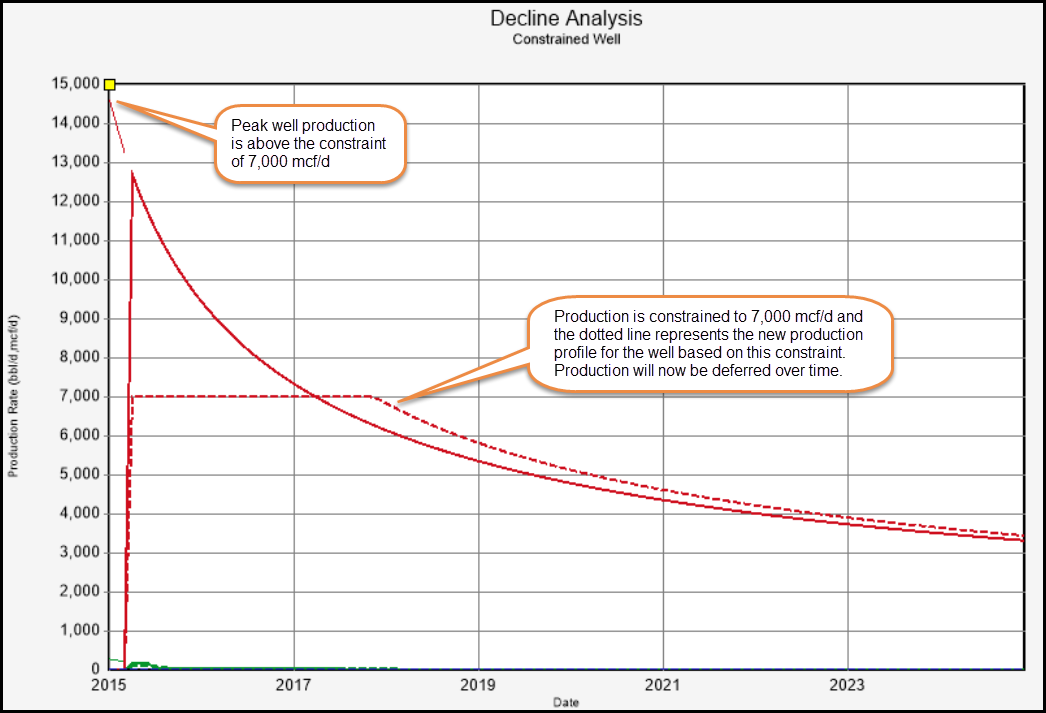

Constraints and Production

Constraints will affect the production and decline curve related wells flowing through the constrained facility or pipeline.

Click image to expand or minimize.

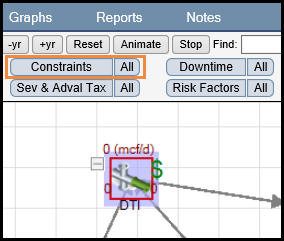

Specifying a Constraint

To set or modify a constraint, select the well or facility you would like to change and click on the “constraints” box:

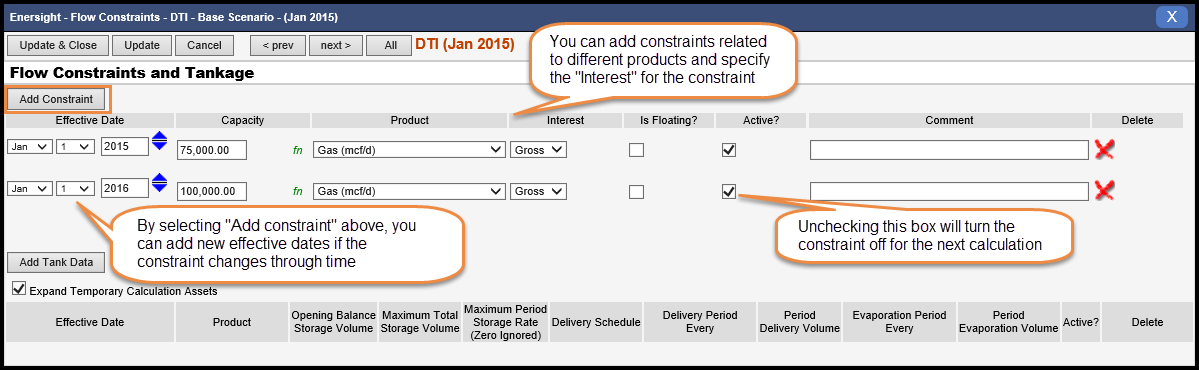

Flow Constraints

A flow constraint imposes a capacity limitation on production through a well or facility. Constraints are defined by at least one product, but will apply to all product as ratios are maintained. Constraints are managed from the Network tab and may also be added in bulk via the CSV loader. The “Flow constraints" box allows you to modify the timing, capacity and products related to each individual constraint:

Click image to expand or minimize.

Multiple constraints can be entered for multiple products at a facility. For example, you might have a gas constraint along with either a sulfur and or water capacity constraint. You should limit the constraints to those that will actually impact your production. Unnecessary constraints will increase your calculation time.

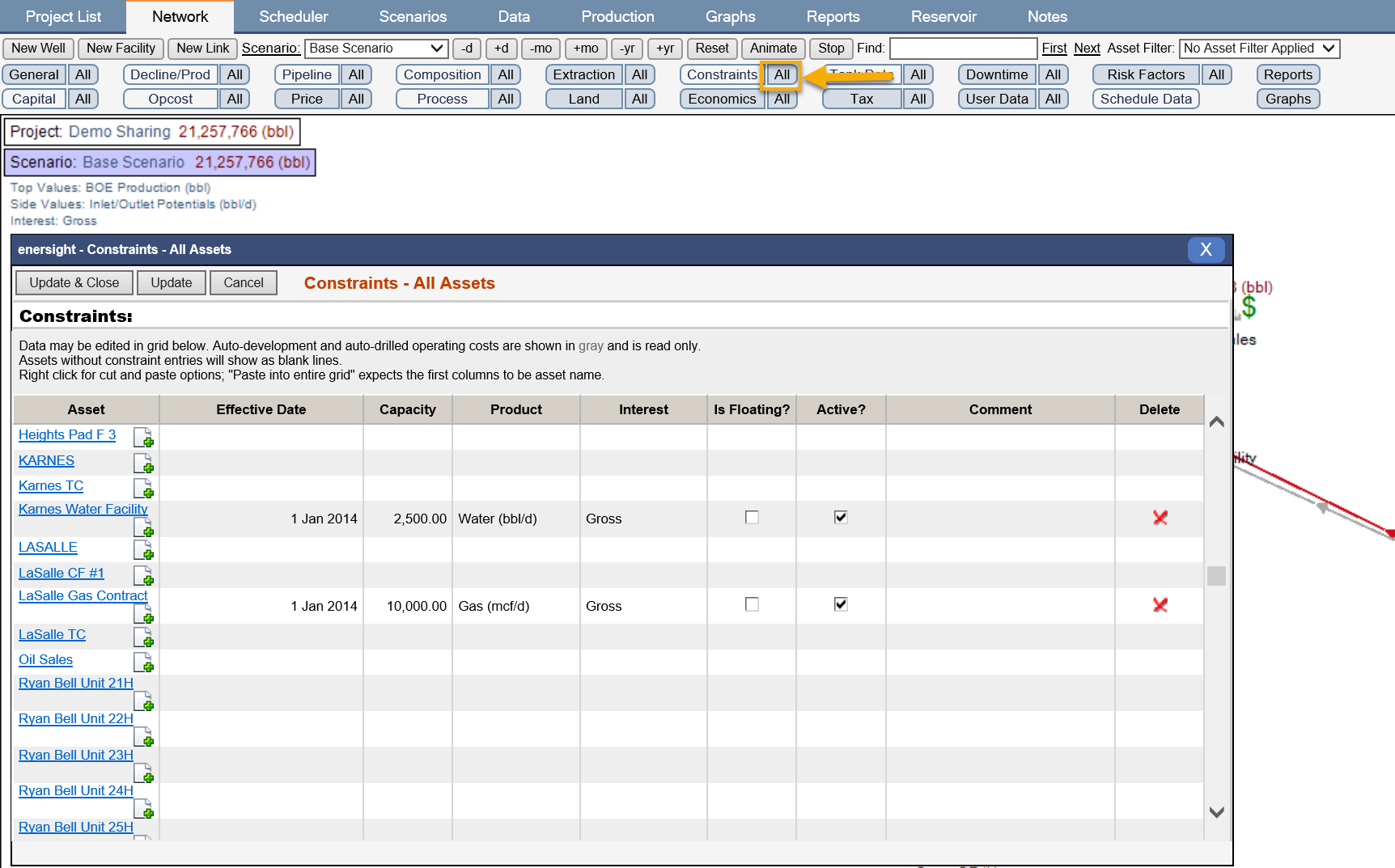

A full set of the constraints within the project may be accessed via the All button next to Constraints, which can be copied/pasted in and out of the application:

Click image to expand or minimize.

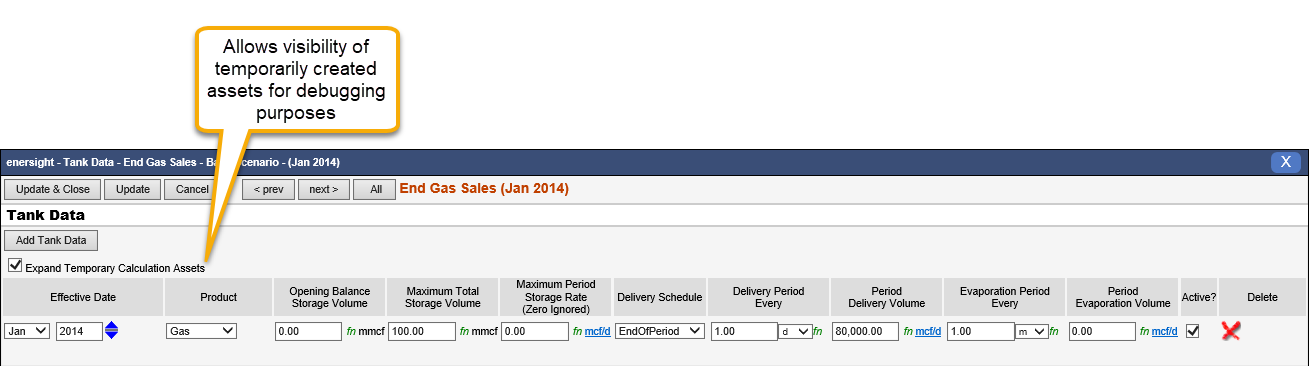

The "Tank Constraints" box allows you to modify the timing, products, storage capacity, delivery and evaporation details related to each individual tank.

Click image to expand or minimize.